Formation of provisional anchoring of wall molded to the ground, with an inclination of 30 ° in relation to the horizontal plane, up to 17.5 m in length, to guarantee the stability of the molded wall during the excavation work of the earth, until the wall gains rigidity through its connections with the rest of the structure, for less than 2 years of service.

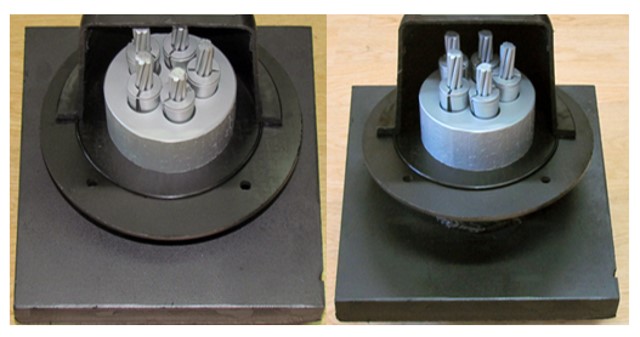

Temporary – Anchorages with a useful life of less than 9 months. The core of the cord is made up of pretensioning steel strands, unprotected in the bulb area and self-protected in the free zone. Available with a single injection tube. The cord is centered and removed from the wall of the hole by centerers.

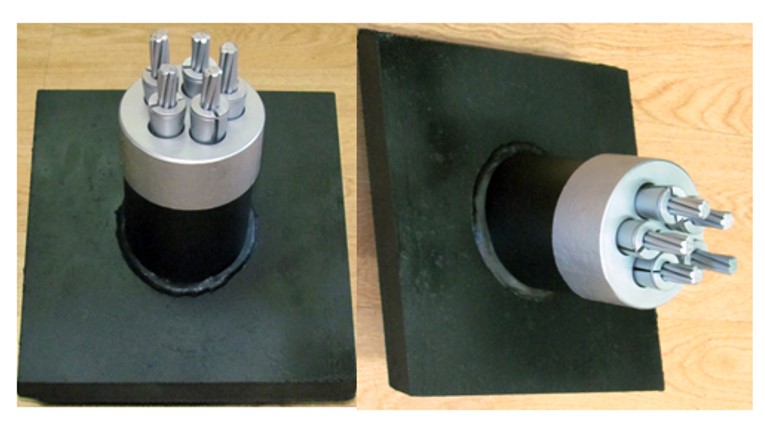

Permanent – Anchorages with a useful life of more than 9 months which require special protection. The core of the cord consists of unprotected pretension steel cables in the bulb area and self-protected in the free area. the Cord is installed inside a corrugated sheath along its entire length. for primary injection, two tubes are applied, housed within the corrugated sheath. In anchorages that require reinjection, a third tube is installed outside the sheath. to guarantee the separation of the cord from the hole wall, spacers are used in the bulb area

Tie rods – The core of the cord is made up of self-pretensioning steel cables protected throughout their length with consistent mass and an individual high-density polyethylene (HDPE) sheath. The cord is installed in a HDPE sheath. The space between individual and collective hems can be sealed with syrup or grease if necessary.

It consists of the following works: land extraction with mechanical means, through drilling of the molded wall and the ground, with a 114 mm outside diameter mold; introduction of 3 cables formed by 0.6 “(15.2 mm) braided steel strands of nominal diameter, lubricated and sheathed in PE tube;

Pressure injection through the global single injection system (IU), CEM I 42.5N cement layer, with a water / cement ratio of 0.4, dosed in weight, for protection and bulb formation;

Fixing the cables to the anchor head formed by support plate and steel wedge; tensioning of the cables with multifilament cable tensioner and hydraulic central, once the prey of the cement lay wins;

sealing of drilling and start-up. Including p / p for assembly, disassembly and removal of equipment, perforation of the wall and terrain, distension of the anchorage once the final stabilization of the wall is finished, cleaning and removal of the debris

Certificado para comercialização, instalação ou manutenção de equipamentos e sistemas SCIE Nº3325

Certificado para comercialização, instalação ou manutenção de equipamentos e sistemas SCIE Nº3325  Certificado de Empreiteiro de obras públicas Nº137213

Certificado de Empreiteiro de obras públicas Nº137213