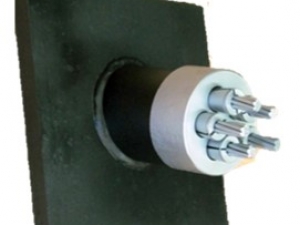

High strength threaded rod system

SPAM bars are made of special high-strength steel, with diameters between 12 and 75 mm. With integral thread. The standard length is 12m.

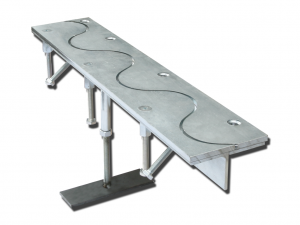

Applications: In pre-tensioned joints (concrete-concrete, concrete-steel, steel-steel), in pre-tensioned constructions of grooves and blocks, as anchor bolts for tension joints, as tie rods in structures, in temporary or partial pretension of piles, pre-tensioning slabs, stabilization of retainers and slopes, stabilization slabs (without joints), tensioners and tie rods in beam reinforcement formwork, slabs, walls and arches, reinforcement of metal structures, lifting of heavy weights, continuity of beams on bridges, etc.

ACCESSORIES

The VSP system bar has a complete range of accessories complementary to the various applications of its bars. Among them, we can highlight:

- Ferrules

- Nuts and locknuts

- Plates

- Anchor Parts

- Cones

- Expansion Tacos.

thread system makes it possible by cutting and joining sleeves bars anywhere, which greatly facilitates their use, and also facilitates placement.

The most significant characteristics of the VSP bar are:

- Hot rolling manufacturing process.

- Threaded rod along its length

- Ability to cut and attach the bars at any point on the bar.

- Thick, resistant thread, with self-cleaning effect, which supports the hardness of the treatment work.

- It guarantees perfect adhesion to concrete, cement mortar, resin …

- Corrosion protection for different systems

- Stainless steel bar available.

- High quality standards guaranteed by ISO 9001

- Continuous technological development of sugarcane and accessories

- Immediate response to customer needs.

CORROSION PROTECTION

According to the aggressive environment and considering the life of the element, steel must have an adequate system of protection against corrosion. They listed below the different protection systems available:

- Vaseline wrapping tape (Vaseline tape)

- Heat by shrinking sleeves. (Heat shrinkable)

- Epoxy

- Hot dip galvanized

- Stainless steel

- DCP (Double corrosion protection)

Certificado para comercialização, instalação ou manutenção de equipamentos e sistemas SCIE Nº3325

Certificado para comercialização, instalação ou manutenção de equipamentos e sistemas SCIE Nº3325  Certificado de Empreiteiro de obras públicas Nº137213

Certificado de Empreiteiro de obras públicas Nº137213