Cortartec ancon 500 is a new high performance tensioning system. It is available in various diameters from 8mm to 42mm in carbon steel and stainless steel.

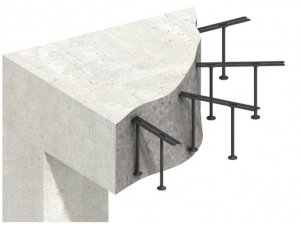

The concrete structures are designed with expansion and contraction joints to allow their movement to occur. Transverse stress connectors are used to transfer the cutting force through these articulated joints. The design of the joint is important for the overall design of the structure to function properly. The range of Cortartec shear connectors offers significant advantages over simple connection fittings. They are more effective in transferring cargo, which accommodates movement and due to their two-part construction, they are simpler to install. The sleeve component is nailed to the formwork and poured into the first pouring, the drilling of the formwork or concrete is not necessary. Once the formwork is removed, the bolt component is pushed into the sleeve, which has already been concreted and is concreted with the second stage.

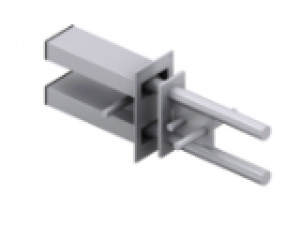

Connector DSD

The DSD is the original two-part, double dowel, shear load connector. The dowel component can move longitudinally within the sleeve to accommodate movement. The connector is available in ten standard sizes and can transfer design loads from around 20kN to over 950kN. The larger connectors can be used in joints up to 60mm wide.

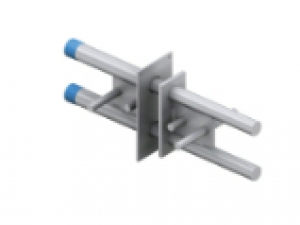

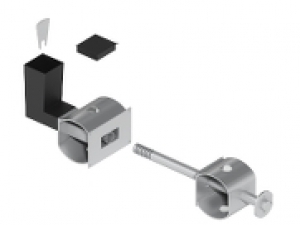

Connector DSDQ

The DSDQ shear load connector uses the same dowel component as the Ancon DSD, but the cylindrical sleeve is contained within a rectangular box section to allow lateral movement in addition to the longitudinal movement. Nine standard sizes can be used to transfer design loads from around 30kN to over 950kN.

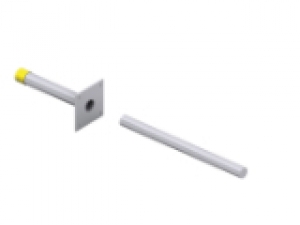

Connector ESD

The ESD is a single dowel shear connector and is available in four sizes with each size available in two lengths. Ancon ESD shear connectors are used where the slab or wall is too thin for Ancon DSD, and where loads are small.

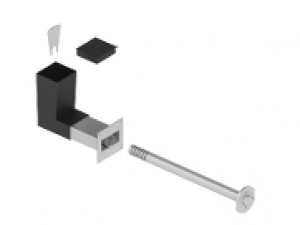

Connector ESDQ

The ESDQ shear load connector uses the same dowel as the Ancon ESD, but the cylindrical sleeve is contained within a rectangular box section to allow lateral movement in addition to longitudinal movement.

Connector ED

The ED is a low cost dowel connector for use in floor slabs where alignment is important but loads are small. The single dowel shear connector is available in four sizes with each size available in two lengths.

Connector HLD

The Ancon HLD is a two-part, high load, shear connector. The dowel component moves longitudinally within the sleeve to accommodate movement. The connector is available in seven sizes with design capacities from 24kN to over 500kN.

Connector E-HLD

The Ancon E-HLD allows the connection of new slabs to diaphragm walls or secant pile walls in basement construction. The dowel component is resin-fixed in the wall.

ESDQ-L20

The ESDQ-L Lockable Dowel allows initial movement to take place and then, after a predetermined time period (generally 60-120 days), is locked with a two-part epoxy resin poured into the L-shaped grout box.

Connector HLDQ-L30

The HLDQ-L30 is a high load Lockable Dowel with a design capacity of up to 136kN.

Connector Staisil – HLD

The Ancon Staisil-HLD Acoustic Dowel is designed to dampen impact noise in multi-storey developments by decoupling concrete components such as stair landings. The 22mm diameter stainless steel dowel bar is located in a sound absorbing sleeve.

Cortartec MULTIJOINT is an all-in-one solution for loading transfer, contraction of cement, armored edge protection and formwork. It is ideal for use in factories, warehouses, distribution centers and other applications where slabs are subject to high loads and vehicle traffic. Its use can distort slab depth, saving time and materials and avoid uneven vertical settlements between slabs. Individual ancon plate bushings are an efficient means of transferring shear loads and accommodating grinding on load bearing ground floors. The 75/10 ancon ADD is suitable for most applications. Where greater capacity or more is required than the average set widths are anticipated, the ancon AHM 100/10 of the system should be considered. The larger steel plate provides a greater surface area to reduce the rolling stresses on the cement. This dowel normally provides a 30% increase in the capacity for joints of more than 20 mm in slabs greater than 250 mm.

Certificado para comercialização, instalação ou manutenção de equipamentos e sistemas SCIE Nº3325

Certificado para comercialização, instalação ou manutenção de equipamentos e sistemas SCIE Nº3325  Certificado de Empreiteiro de obras públicas Nº137213

Certificado de Empreiteiro de obras públicas Nº137213