- Rod – Coil rod – Molded rod – Welded mesh

Steel is the backbone of many buildings. Therefore, quality and durability are essential. We also know where and when individual steel grades are worth choosing. In short: We offer our experience and knowledge to choose the right stainless steel to protect you and help save our customers money! The stainless steel reinforcement does not rust. Used for reinforced concrete structures it is the optimal way to avoid damage related to the corrosion of concrete and, subsequently, the high cost of its maintenance and risk. Our technicians know exactly where it is worth using. With the intelligent use of stainless steel we ensure a very positive result and without impact on the final cost of the project.

In order to ensure consistently high quality, our production and quality assurance are monitored continuously by several international supervisory bodies, such as UK Cares, MPA Germany, Kontrollrådet in Norway, and Technology force in Denmark. Continuous internal checks are also carried out in our own laboratory. All data and results are shown in our database.

Certificates indicating chemical composition and mechanical properties accompany all supplies of stainless steel.

Our products can be identified at any time, even after being applied to concrete, due to the exclusive markings applied to the bars during their production.

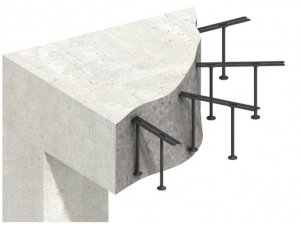

The ribbed stainless steel rod is the smart, economical and corrosion-free choice for construction.

- Wastewater treatment plants

- Nuclear power plants

- Military installations

- Laboratories with sensitive measuring equipment

- Superstructures with special / external design

- Refineries

- Pier

- Dams

- Foundations

- Historic buildings

- Petrochemicals

- Industrial complexes

- Bridges

- Tunnels

- Parking lots

- Airports

- Offshore Industry

- Port facilities

Stainless steel ribbed rods

-

All types of reinforcement bars for reinforced concrete reinforcements in stainless steel with diameters from 3 to 50 mm.

-

Ribbed rods are supplied in lengths from 6,000 mm to 12,000 mm or cut to lengths according to the order.

-

Weight per tie: up to about 2,500 kg.

Stirrups

-

We can produce all types of stainless steel reinforcement stirrups. We cut and bend the stirrups according to the molding plan and material specifications, provided by the customer and deliver the finished products directly to the construction site.

-

The stirrups are folded specifically according to the customer’s drawings and the molding plan.

-

To avoid the risk of misunderstandings, standard flexion rules should be considered.

-

We use the BS8666: 2005 standard standards. Other standards are available upon request.

-

Important: National product standards have different requirements regarding the bending radii and the mechanical characteristics of reinforcing stainless steel. Therefore, it is essential that all orders are specified according to a standard, and that this is indicated on the order.

Coils

-

Ribbed steel for reinforcement reinforcements in stainless steel in diameters from 3 to 16 mm, available in coil.

-

Weight per coil: approx. 2000 kg.

-

Outside diameters: approx. 1050 mm.

-

Internal diameters: approx. 640 mm.

-

Height: approx. 640 mm.

-

The coils are tied with 4 x 32 mm plastic strips.

The characteristics of stainless steel

-

Conventional reinforcement is made from “black steel”, that is, low carbon steel alloy, with a content of about 0.2% carbon, the most essential alloy element.

-

By adding elements to the alloy such as chromium, nickel and molybdenum, a considerable improvement in the corrosion resistance of steel is achieved.

According to EN 10088-1, the classification of stainless steel has a minimum content of 10.5% chromium and a maximum content of 1.2% carbon.

Stainless steel alloys, used for reinforcement reinforcements, often have a higher chromium content, as well as the addition of nickel and eventually molybdenum to further increase corrosion resistance.

A large number of steel alloys can be correctly defined as stainless steel due to the chromium content, but the corrosion resistance differs greatly depending on the composition of the specific alloy.

In addition to the mechanical characteristics of stainless steel alloys being different, they mainly depend on the microstructures of the alloys.

-

Stainless steel is divided into four main groups, depending on the steel’s microstructures:

-

Martensitic and Ferritic:

Martensitic and ferritic stainless steels are not used for reinforcement reinforcements, due to their proportionally low resistance to corrosion and the risk of micro fractures.

-

Austenítico:

Austenitic stainless steels combine good corrosion resistance with high strength. Therefore, they are very popular for a large number of applications, including reinforcement of concrete structures.

Austenitic stainless steels combine good corrosion resistance with high strength. Therefore, they are very popular for a large number of applications, including reinforcement of concrete structures. -

Duplex (Austenitic-Ferritic):

Duplex alloys combine the best qualities of austenitic and ferritic steels. This means that duplex alloys offer even better corrosion resistance than austenitic steel and, at the same time, have good weldability and molding. The processing of duplex steels is, however, more demanding.

Stainless steel mesh

-

The mesh offers real advantages in comparison to the use of rods tied in construction.

-

AThe welded mesh does not need to be tied in place. The mesh saves time and labor costs and ensures accuracy. The mesh welded to the machine reduces the risk of physical injury at the site.

-

We supply the most common European sizes and keep stock at the factory for fast and efficient delivery..

-

We have a committed team ready to work with our clients to meet specific project requirements. This includes special dimensions of the mesh, panel or rods.

| Alloy Eurocode | Diameter mm | Panel size mm | Mesh (mm) | overhangs (mm) L/B | Nominal weight kg/item |

|---|---|---|---|---|---|

| 1.4571 | 3.00 | 5000×2150 | 50×50 | 25/25 | 24.10 |

| 1.4571 | 3.00 | 5000×2150 | 75×75 | 25/25 | 16.19 |

| 1.4571 | 4.00 | 5000×2150 | 50×50 | 25/25 | 45.00 |

| 1.4571 | 4.00 | 5000×2150 | 100×100 | 50/25 | 22.62 |

| 1.4571 | 4.00 | 5000×2150 | 150×150 | 25/25 | 14.96 |

| 1.4362 | 5.00 | 5000×2150 | 100×100 | 50/25 | 34.80 |

| 1.4362 | 5.00 | 5000×2150 | 150×150 | 25/25 | 23.70 |

| 1.4362 | 6.00 | 5000×2150 | 100×100 | 50/25 | 48.94 |

| 1.4362 | 6.00 | 5000×2150 | 150×150 | 25/25 | 33.32 |

| 1.4362 | 8.00 | 5000×2150 | 100×100 | 50/25 | 87.00 |

| 1.4362 | 8.00 | 5000×2150 | 150×150 | 25/25 | 59.24 |

Leagues

-

We can supply stainless steel reinforcement in the following alloys and dimensions.

-

If there is a need for alloys or dimensions not mentioned in the table, please contact us for more information.

| Alloy according to EN 10088-1 | Common description | Production process | Dimensions (mm) | Arminox bar mark |

|---|---|---|---|---|

| 1.4301 | 304 | Hot rolled wire | 3-16 20-50 | /// vv /// Variable |

| 1.4436 | 316 | Thread worked | 3-16 | /// vvv /// |

| 1.4571 | 316ti | Thread worked | 3-16 | /// x /// x /// x /// |

| 1.4362 | Duplex | Hot rolled wire | 6-12 12-32 | /// x /// x /// x // Variable |

| 1.4462 | Duplex | Hot rolled | 16-40 | Variable |

How to choose the alloy

-

The choice of alloy depends on the environment in which the structure is to be used. Arminox recommends the following applications for our alloys:

Recommended alloy according to the environment class:

| Environment Class | Aggressiveness | Recommended League |

|---|---|---|

| Passive | – | High-performance reinforcing steel |

| Moderate | – | High-performance reinforcing steel / 1.4301 |

| Aggressive | Low

Medium High |

1.4301

1.4436 / 1.4362 / 1.4571 1.4462 |

| Extra aggressive | – | Superaustenitic / Super duplex |

Definition of aggressive environment:

| Environment | Example | It is made |

|---|---|---|

| Low | Indoor industrial areas | Carbonization |

| Medium | Marine and coastal areas. Road defrosting salt | Chloride penetration |

| Alto | Extreme temperature differences. Extreme chloride concentrations. Extreme environmental conditions | Carbonization. Chloride penetration from others |

Certificado para comercialização, instalação ou manutenção de equipamentos e sistemas SCIE Nº3325

Certificado para comercialização, instalação ou manutenção de equipamentos e sistemas SCIE Nº3325  Certificado de Empreiteiro de obras públicas Nº137213

Certificado de Empreiteiro de obras públicas Nº137213